Larke Machine

Larke MachineRequest A Quote

Waukesha, WI | 262-547-5760At Larke Machine, we present ourselves as a precision manufacturing partner specializing in CNC machining and broaching services that support high-performance industrial applications. We work with a wide range of metals and alloys, producing components that require tight tolerances, accurate geometry, and consistent repeatability. By combining modern CNC equipment with deep expertise in broaching processes, we deliver parts that meet demanding dimensional and functional requirements while maintaining efficiency across both short and long production runs. We approach every project with an engineering-driven mindset, collaborating closely with customers to understand design intent, material behavior, and downstream assembly needs. Our CNC machining capabilities allow us to produce complex features, intricate profiles, and multi-axis components with reliable precision, while our broaching expertise enables us to create internal and external forms such as splines, keyways, and specialized profiles with clean finishes and exact alignment. Through careful tooling selection, optimized setups, and disciplined process control, we ensure that each part integrates seamlessly into our customers’ products and manufacturing workflows. We reinforce our technical capabilities with responsive communication, dependable turnaround times, and a commitment to long-term partnership. Our team provides design-for-manufacturability insight, process optimization, and consistent quality assurance to help customers reduce risk and maintain production efficiency. By blending advanced machining technology, skilled craftsmanship, and a customer-focused approach, we position ourselves as a trusted resource for CNC machining and broaching services that deliver accuracy, durability, and confidence on every project.

Broaching

Broaching CNC Machining

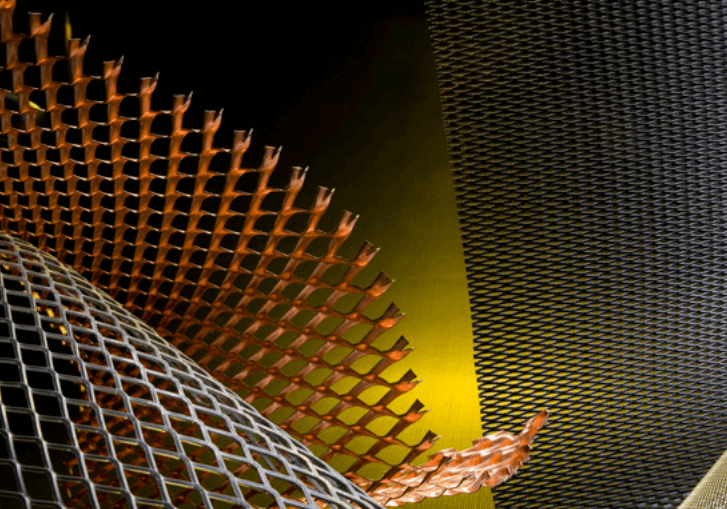

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

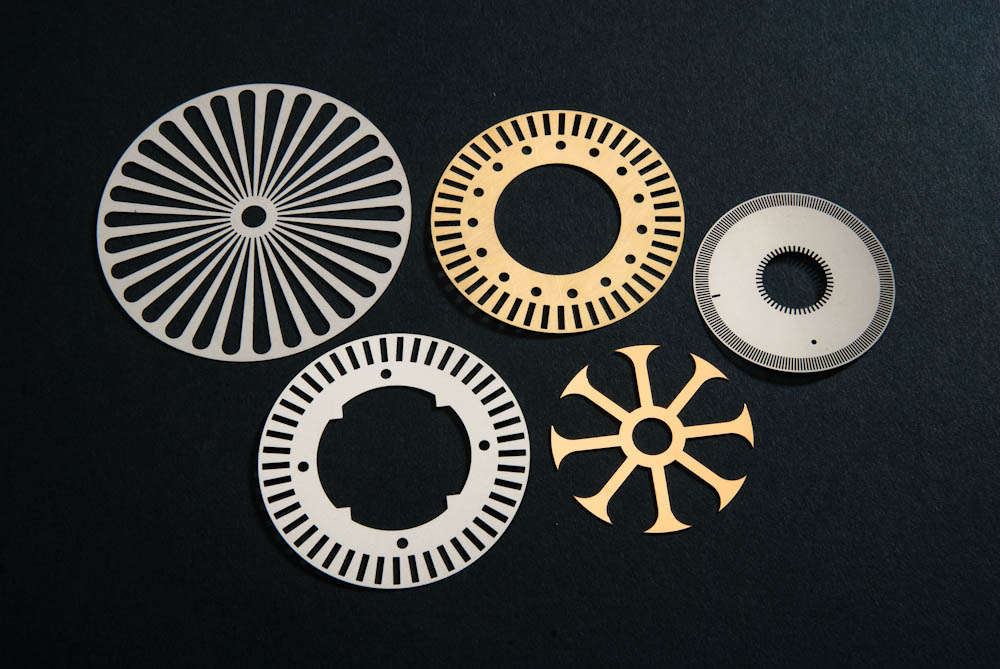

Laser Cutting Metal Etching

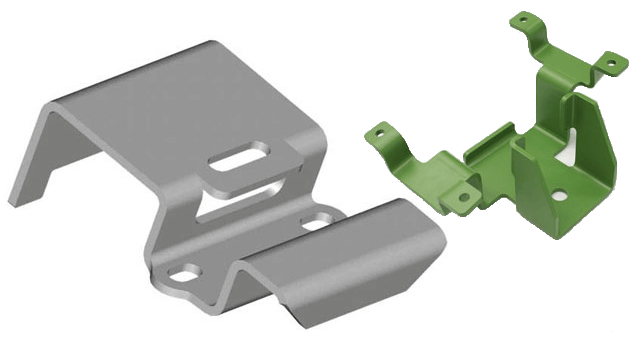

Metal Etching Metal Fabrication

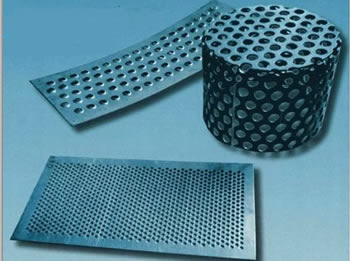

Metal Fabrication Perforated Metals

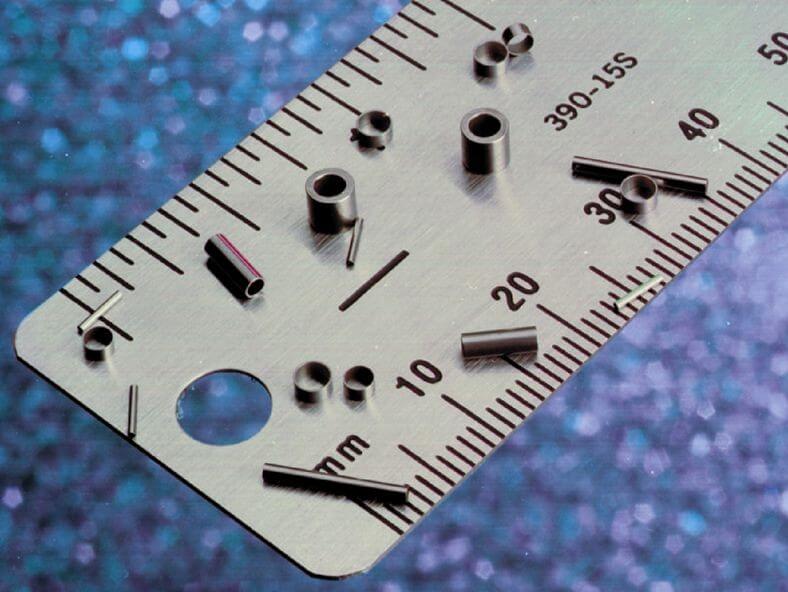

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services